Chifukwa chiyani tiyenera kulumikiza vias mu PCB?

Kuti akwaniritse zofuna za makasitomala, mabowo a board ayenera kulumikizidwa.Pambuyo pochita zambiri, ndondomeko yazitsulo ya aluminiyamu ya pulagi imasinthidwa, ndipo ukonde woyera umagwiritsidwa ntchito kumaliza kukana kuwotcherera ndi plug dzenje la board board, zomwe zingapangitse kupanga kukhala kokhazikika komanso kodalirika.

Via hole imagwira ntchito yofunika kwambiri pakulumikizana kwa mabwalo.Ndi chitukuko cha makampani amagetsi, imalimbikitsanso chitukuko cha PCB, ndipo amaika patsogolo zofunika apamwamba kwaKupanga ndi kusonkhanitsa PCBluso.Tekinoloje ya pulagi ya hole idakhalapo, ndipo izi ziyenera kukwaniritsidwa:

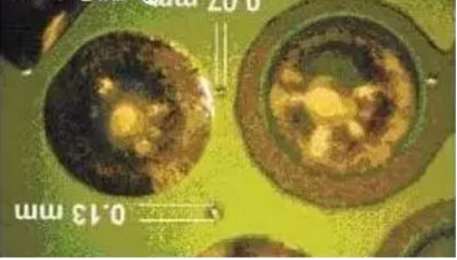

(1) Mkuwa womwe uli pabowo ndi wokwanira, ndipo chigoba cha solder chimatha kulumikizidwa kapena ayi;

(2) Payenera kukhala malata ndi lead mu dzenje, ndi zina makulidwe chofunika (4 microns), palibe solder kukana inki mu dzenje, kuchititsa malata kubisika m'mabowo;

(3) Payenera kukhala bowo la pulagi ya solder resistance mu dzenje, lomwe silimaonekera, ndipo pasakhale mphete ya malata, mikanda ya malata ndi yathyathyathya.

Ndi chitukuko cha zinthu zamagetsi motsogozedwa ndi "zopepuka, zoonda, zazifupi ndi zazing'ono", PCB ikukulanso ku kachulukidwe kwambiri komanso zovuta kwambiri.Chifukwa chake, ma PCB ambiri a SMT ndi BGA adawonekera, ndipo makasitomala amafunikira mabowo oboola akamayika zida, zomwe zimakhala ndi ntchito zisanu:

Ndi chitukuko cha zinthu zamagetsi motsogozedwa ndi "zopepuka, zoonda, zazifupi ndi zazing'ono", PCB ikukulanso ku kachulukidwe kwambiri komanso zovuta kwambiri.Chifukwa chake, ma PCB ambiri a SMT ndi BGA adawonekera, ndipo makasitomala amafunikira mabowo oboola akamayika zida, zomwe zimakhala ndi ntchito zisanu:

(1) Pofuna kupewa dera lalifupi chifukwa cha malata kudutsa mu chinthu pamwamba pa PCB pa yoweyula soldering, makamaka pamene ife kuika kudzera dzenje pa BGA PAD, choyamba tiyenera kupanga pulagi dzenje ndiyeno golide plating atsogolere BGA soldering. .

(2) Pewani zotsalira zotsalira pamabowo;

(3) Pambuyo phiri pamwamba ndi chigawo msonkhano wa fakitale zamagetsi, ndi PCB ayenera kuyamwa vacuum kupanga mavuto zoipa pa makina kuyezetsa;

(4) Kuletsa pamwamba solder kuti asalowe mu dzenje, ndi kuchititsa soldering zabodza ndi kukhudza phiri;

(5) letsani mkanda wa solder kuti usatuluke panthawi yowotchera, ndikupangitsa kuti pakhale njira yayifupi.

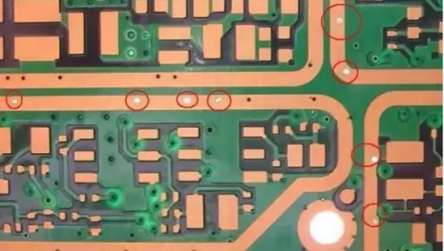

Kuzindikira kwaukadaulo wa plug hole podutsa dzenje

ZaMsonkhano wa SMT PCBbolodi, makamaka kuyika kwa BGA ndi IC, pulagi yodutsa dzenje iyenera kukhala yathyathyathya, yopingasa ndi yopingasa kuphatikiza kapena kuchotsera 1mil, ndipo pasakhale malata ofiira m'mphepete mwa dzenje;kuti akwaniritse zofunikira za kasitomala, njira yolumikizira dzenje kudzera pabowo imatha kufotokozedwa ngati multifarious, kuyenda kwa nthawi yayitali, kuwongolera njira zovuta, nthawi zambiri pamakhala zovuta monga kutsika kwamafuta panthawi yotentha yotentha komanso kuyesa kukana kwamafuta obiriwira ndi kuphulika kwamafuta pambuyo pake. kuchiritsa.Malinga ndi momwe zinthu zimapangidwira, timafotokozera mwachidule njira zosiyanasiyana zamapulagi a PCB, ndikupanga kufananitsa ndi kulongosola bwino panjira ndi zabwino ndi zovuta zake:

Zindikirani: mfundo yogwiritsira ntchito mpweya wotentha ndikugwiritsa ntchito mpweya wotentha kuchotsa solder yochuluka pamwamba pa bolodi losindikizidwa ndi dzenje, ndipo solder yotsalayo imaphimbidwa mofanana pa pad, mizere yosatsekereza ya solder ndi malo oyika pamwamba. , yomwe ndi imodzi mwa njira zothandizira pamwamba pa bolodi losindikizidwa.

1. Pulagi dzenje pambuyo poyatsa mpweya wotentha: kuwotcherera kumtunda kwa mbale → HAL → bowo la pulagi → kuchiritsa.Njira yopanda plug imatengedwa kuti ipangidwe.Pambuyo poyatsa mpweya wotentha, chophimba cha aluminiyamu kapena chotchinga chotchinga cha inki chimagwiritsidwa ntchito kumalizitsa pulagi yamabowo onse ofunikira ndi makasitomala.Pulagi dzenje inki kungakhale photosensitive inki kapena thermosetting inki, mu nkhani ya kuonetsetsa mtundu womwewo wa chonyowa filimu, pulagi dzenje inki ndi bwino ntchito inki yemweyo monga bolodi.Izi zitha kuwonetsetsa kuti pobowo sidzagwetsa mafuta pambuyo poti mpweya wotentha uwonjezeke, koma ndikosavuta kupangitsa inki ya bowo la pulagi kuwononga mbale komanso kusafanana.Ndikosavuta kuti makasitomala apangitse kugulitsa zabodza pakukweza (makamaka BGA).Choncho, makasitomala ambiri savomereza njira imeneyi.

2. Pulagi dzenje musanayambe kutentha kwa mpweya: 2.1 pulagi dzenje ndi pepala la aluminiyamu, limbitsani, perani mbale, ndiyeno tumizani zojambulazo.Izi zimagwiritsa ntchito makina obowola a CNC pobowola pepala la aluminiyamu lomwe likufunika kutsekeredwa, kupanga mbale yotchinga, dzenje la pulagi, kuonetsetsa kuti dzenje lapulagi ladzaza, inki yotsekera, inki yotsekera ingagwiritsidwenso ntchito.Makhalidwe ake ayenera kukhala olimba kwambiri, kusintha pang'ono kwa utomoni, komanso kumamatira bwino ndi khoma la dzenje.Njira zamakono zili motere: pretreatment → pulagi dzenje → mbale yopera → kutengerapo chitsanzo → etching → kuwotcherera mbale pamwamba kukana.Njirayi imatha kuwonetsetsa kuti dzenje la pulagi limakhala losalala, komanso kutentha kwa mpweya sikukhala ndi zovuta monga kuphulika kwamafuta ndi kutsika kwamafuta m'mphepete mwa dzenje.Komabe, njirayi imafuna kukhuthala kamodzi kwa mkuwa kuti makulidwe amkuwa a khoma la dzenje akwaniritse muyezo wa kasitomala.Choncho, ili ndi zofunikira zazikulu zopangira mkuwa wa mbale yonse ndi ntchito ya chopukusira mbale, kuti zitsimikizire kuti utomoni pamtunda wamkuwa umachotsedwa kwathunthu, ndipo pamwamba pa mkuwa ndi woyera komanso wosaipitsidwa.Mafakitale ambiri a PCB alibe nthawi imodzi yokulitsa mkuwa, ndipo magwiridwe antchito amalephera kukwaniritsa zofunikira, chifukwa chake njirayi siyigwiritsidwa ntchito kawirikawiri m'mafakitale a PCB.

(The blank silk screen) (The blank point film net)

We are helpful, attentive and supportive with a proactive approach to help you win in competitive markets. For more information, please email to service@pcbfuture.com.

Nthawi yotumiza: Jul-01-2021